Choosing the Right Steam Boiler

The steam boiler is arguably the most critical component in any industrial facility—it is the heartbeat that drives manufacturing processes, power generation, and essential heating throughout the plant. A boiler system failure can bring an entire operation to an immediate halt, making the selection process a fundamental exercise in risk management, engineering precision, and financial forecasting. Choosing the right boiler is not just a procurement decision; it is a long-term strategic commitment that dictates operational efficiency, compliance, and ultimately, your return on investment (ROI).

I. Initial Assessment: Defining Core Requirements

The selection process begins with a meticulous assessment of the specific demands and constraints of the industrial process it will serve. This defines the baseline technical requirements.

1. Required Capacity, Pressure, and Temperature

The most basic requirement is the boiler’s steam capacity, typically measured in pounds per hour (lb/hr) or tonnes per hour (t/hr). This must meet peak demand plus a safety margin (often 10–20%).

Pressure: The system must meet the minimum pressure required by the highest-pressure user (e.g., turbine, sterilizer, or press). This determines the boiler’s design pressure rating.

Temperature: For superheated steam applications (common in power generation or large turbines), the required temperature dictates specialized boiler construction and superheater elements.

2. Load Profile and Responsiveness

The nature of the industrial load is crucial.

Steady Load: If steam demand is consistent (e.g., continuous chemical processing), a boiler focused purely on high thermal efficiency at a fixed point is ideal.

Fluctuating Load: If demand changes rapidly (e.g., batch processing, sudden surges), the boiler must possess a high turndown ratio (the ratio of maximum output to minimum stable output) and quick ramp-up capability to avoid steam pressure drops.

3. Application Type

Whether the steam is used for process heat, sterilization, or electricity generation impacts regulatory requirements and required purity levels. Process steam often requires lower pressure than power generation steam.

II. Boiler Technology and Design Types (more)

The core of the selection process involves choosing the right physical design based on capacity, pressure, and responsiveness needs.

1. Fire-Tube Boilers

Design: Hot combustion gases pass through tubes surrounded by water in the main vessel.

Advantages: Simple design, lower initial cost, excellent steam quality (large water inventory acts as a buffer), and better suited for low-to-medium steam capacity and pressure (up to 25 t/hr and 20 bar).

Trade-offs: Slower response to load changes, larger physical footprint per unit of output.

2. Water-Tube Boilers

Design: Water circulates through tubes while hot combustion gases flow around them.

Advantages: Capable of producing very high pressure and high capacity steam (essential for utility power plants), faster start-up and rapid response to load changes due to lower water content.

Trade-offs: More complex water treatment requirements, higher maintenance costs, and generally higher initial capital expenditure.

3. Specialty Boilers

Electric Boilers: Ideal for small loads or facilities where fossil fuels are restricted or expensive. Offer near 100% thermal efficiency but depend entirely on electricity cost.

Heat Recovery Steam Generators (HRSGs): Designed to capture high-temperature waste heat (typically from gas turbines or industrial furnaces) to produce steam, dramatically boosting overall system efficiency in Combined Heat and Power (CHP) configurations.

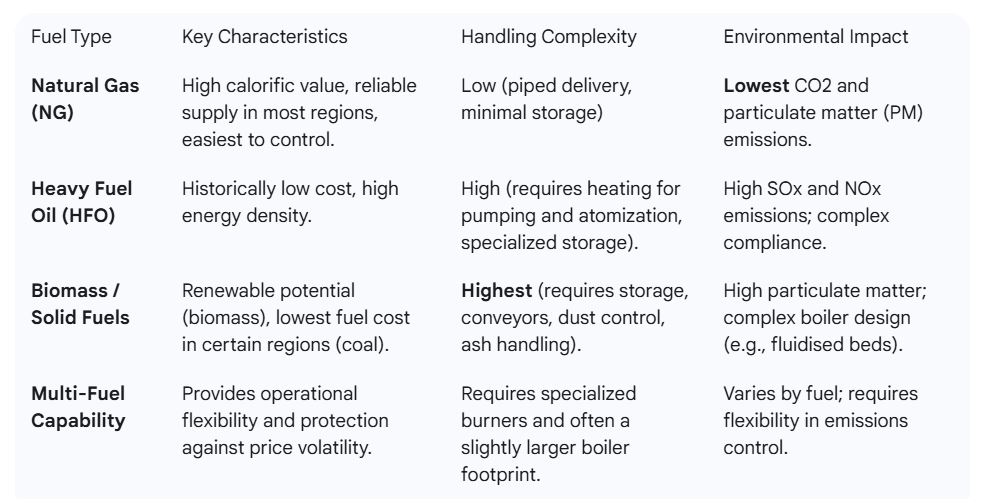

III. Fuel Source Selection: Economic and Environmental Impact

The choice of fuel is a multi-faceted decision driven by regional availability, cost volatility, environmental regulations, and handling complexity.

IV. Efficiency, Emissions, and Sustainability

Modern boiler selection must prioritize efficiency to reduce lifetime operating costs and compliance to avoid regulatory penalties.

1. Thermal Efficiency

Measured as the percentage of fuel energy converted into usable steam. While new units often promise 85–95% efficiency, maintaining this requires auxiliary equipment:

Economizers: Use exhaust flue gas heat to preheat the feedwater, recovering energy that would otherwise be lost up the stack.

Air Preheaters: Use flue gas heat to warm the combustion air supplied to the burner, improving the ignition and combustion process.

2. Emissions Control (NOx and SOx)

Compliance with stringent local and national air quality standards is mandatory.

NOx Reduction: Achieved primarily through Low NOx burners and, for larger systems, Selective Catalytic Reduction (SCR) or Selective Non-Catalytic Reduction (SNCR) systems installed in the flue gas path.

SOx Reduction: Primarily managed by choosing lower sulfur fuels, or by installing scrubbers to remove sulfur oxides from the flue gas.

V. Critical Auxiliary Systems

The boiler is a component within a complex system; the quality of the supporting equipment is equally important for overall reliability.

1. Water Treatment System

Improper boiler water treatment is the leading cause of boiler failure, corrosion, and scale formation. The system must include:

Deaerator: Essential for removing dissolved oxygen and carbon dioxide, which cause pitting and corrosion.

Softeners/Demineralizers: Remove hardness-causing minerals (calcium, magnesium) to prevent scale buildup on heat transfer surfaces, which severely reduces efficiency.

Chemical Dosing: Precise injection systems for scale inhibitors, oxygen scavengers, and pH control agents.

2. Burner and Control Systems

The burner dictates combustion quality, efficiency, and emissions. Key features include a high turndown ratio for load flexibility and modern electronic modulating control for precise fuel-air mixing. The entire system should be managed by a robust PLC/SCADA system for real-time monitoring and automation.

VI. Financial and Practical Considerations

The final decision must be evaluated based on long-term financial viability and practical site constraints.

1. Total Cost of Ownership (TCO)

Focusing solely on the initial capital cost is a common mistake. The TCO evaluates the full cost over the boiler’s lifespan, including:

Initial Capital Cost (Equipment purchase and installation)

Fuel Costs (Dominant factor)

Maintenance and Repair Costs (Parts, labour)

Water and Chemical Costs

Regulatory Compliance Costs

A more expensive, highly efficient boiler often provides a significantly lower TCO due to reduced fuel consumption over decades of operation.

2. Site and Maintenance Factors

Footprint: Is there sufficient space for the boiler, auxiliaries (deaerator, tanks), and fuel storage? Water-tube boilers can sometimes offer a more compact vertical solution.

Accessibility: The boiler must be easily accessible for routine tube cleaning, internal inspections, and burner maintenance.

Lead Time: Production and delivery timeframes must align with the project schedule.

In summary, selecting the right steam boiler demands a holistic engineering perspective that weighs current process requirements against future sustainability, regulatory compliance, and long-term financial performance. This decision is best guided by an experienced partner capable of performing detailed load profiles and TCO analysis.

Daha fazlasını keşfetmek ister misiniz?

Bizimle iletişime geçin. İhtiyaçlarınıza yönelik en doğru çözümü, ürünü veya hizmeti sunmaktan memnuniyet duyarız.

Fevol provides innovative industrial process solutions, driving sustainability and efficiency in the energy sector. We engineer and provide smart, reliable systems for a greener future.

Useful Links

Our Expertise

Contact Us

Barbaros Mahallesi, Begonya Sk. Nidakule Ataşehir Batı No:1 Ataşehir / Istanbul, Türkiye

info@fevoltech.com

Copyright 2025, Fevol. All Rights Reserved.