Industrial burners

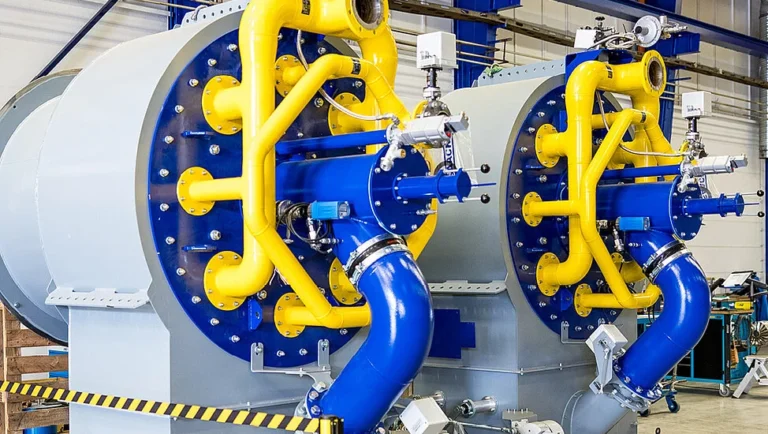

Industrial burners are the powerhouse components that transform fuel into precisely controlled thermal energy, driving processes across every major sector—from power generation and metallurgy to petrochemicals and food processing.

Burner solutions

At FEVOL, we specialize in providing comprehensive Burner Solutions that move beyond standard equipment supply. We recognize that efficient combustion is not a one-size-fits-all process; it requires deep customization based on fuel type, emission targets, and specific thermal load requirements.

Our portfolio includes advanced single-fuel, dual-fuel, and multi-fuel burners designed for exceptional performance across various thermal processes, including steam generation, hot water production, and specialized furnace applications.

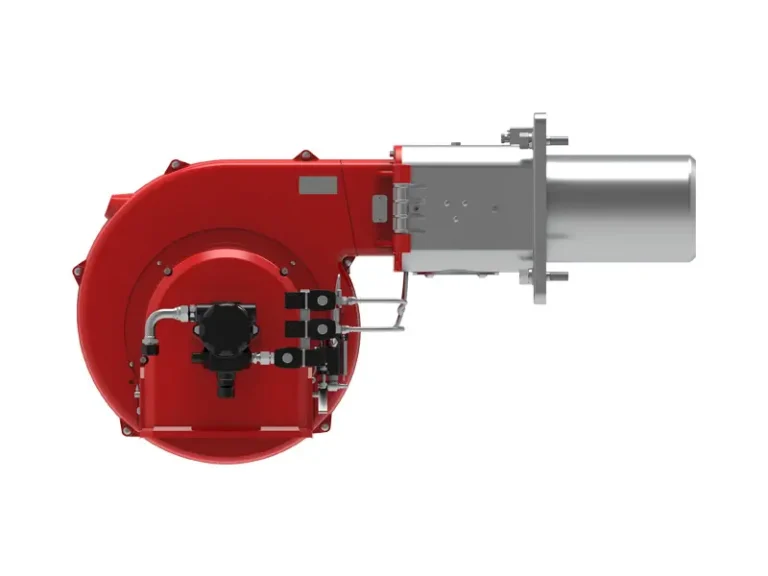

Gas burners

Design & Technology: Utilizes advanced forced-draft monobloc or duobloc technology, engineered for optimal mixing of fuel and air to ensure stable and complete combustion.

Fuel Type: Designed specifically for natural gas (NG) and liquefied petroleum gas (LPG), with rapid changeover capability for dual-fuel systems as an option.

Capacity Range: Available in a wide thermal output range, typically from 200 kW up to 30 MW (thermal), precisely matched to boiler or furnace demands.

Emission Control: Features cutting-edge Low-NOx and Ultra-Low-NOx head designs, including surface stabilization or flue gas recirculation (FGR) systems, to meet stringent environmental compliance.

Air/Fuel Ratio Control: Equipped with a high-precision electronic control system (often servomotor-driven) for continuous, dynamic regulation of the air-to-fuel ratio across the entire modulation range.

Modulation Type: Available with two-stage (Hi/Low/Off) or fully modulating control (1:4 up to 1:10 turndown ratio) for superior thermal stability and energy saving.

Safety Integration: Includes comprehensive safety train components (gas valves, pressure switches, leak detection) and an advanced Burner Management System (BMS) for fail-safe operation and sequence control.

Maintenance: Designed for ease of maintenance, featuring accessible combustion heads and quick-disconnect fittings to minimize downtime.

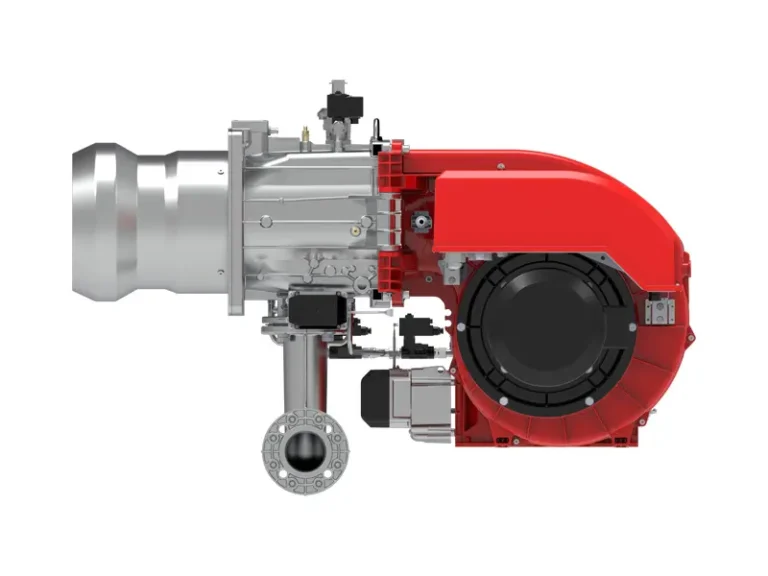

Oil burners

Design & Technology: Incorporates robust, heavy-duty mechanical atomization or steam/air assisted atomization technology, ensuring fine fuel dispersion for efficient and sustained ignition.

Fuel Type: Specifically designed to accommodate heavy oils (HFO, Mazut), light oils (Diesel, Kerosene), and biofuels, optimized for reliable preheating and pumping requirements.

Capacity Range: Available in a broad thermal output range, typically from 200 kW up to 30 MW (thermal), precisely engineered for large boiler plants and process heaters.

Emission Control: Utilizes proven techniques such as staged air or advanced atomizer tips to manage soot formation and reduce particulate matter (PM) emissions, ensuring compliance with industrial air quality standards.

Viscosity and Preheating: Equipped with integrated electrical or steam heating systems and precise temperature control to maintain optimal fuel viscosity for effective atomization.

Modulation Type: Features advanced rotary cup or pressure jet technology, offering fully modulating control (high turndown ratio) to adapt smoothly to varying thermal demands.

Safety Integration: Includes comprehensive safety components such as high-limit temperature controls, leak detection for oil lines, and a dedicated Pump and Heater Set (PHS) integrated with the Burner Management System (BMS).

Maintenance: Built with accessible components, easy-to-replace nozzle assemblies, and robust refractory lining to withstand high combustion temperatures and minimize servicing frequency.

Our Commitment to Your Operation

High Thermal Efficiency and Fuel Economy

All our products are equipped with advanced combustion technology. This ensures maximum heat recovery while keeping fuel consumption to a minimum, significantly reducing long-term operating costs.

Low Emissions and Environmental Compliance

Utilization of cutting-edge Low-NOx and Ultra-Low-NOx technologies to ensure strict compliance with local and international environmental regulations.

Advanced Automation and Digital Control

Integration with advanced PLC-based control systems for fully automated operation, precise air-fuel ratio management, and enhanced safety monitoring.

Superior Safety and Reliability

All our designs adhere to the highest international safety standards (such as ASME and EN). Equipped with redundant safety systems, pressure relief valves, and automatic safety shutdown mechanisms, our products promise a long, trouble-free operating life.

Interested in discovering more?

Contact us today! We’re eager to assist you in finding the perfect solution, product, or service.

Fevol provides innovative industrial process solutions, driving sustainability and efficiency in the energy sector. We engineer and provide smart, reliable systems for a greener future.

Useful Links

Our Expertise

Contact Us

Barbaros Mahallesi, Begonya Sk. Nidakule Ataşehir Batı No:1 Ataşehir / Istanbul, Türkiye

info@fevoltech.com

Copyright 2025, Fevol. All Rights Reserved.