Gas turbines

Gas turbines are powerful, highly efficient rotating machinery that serve as the prime movers in modern power generation and heavy industrial drive applications. These advanced thermal engines convert the chemical energy of gaseous or liquid fuels into mechanical work and heat, driving electrical generators or industrial compressors. Known for their high power density, rapid start-up capability, and operational flexibility, gas turbines are a critical foundation for utility-scale power plants, combined cycle systems, and decentralized industrial facilities requiring reliable, high-capacity energy supply.

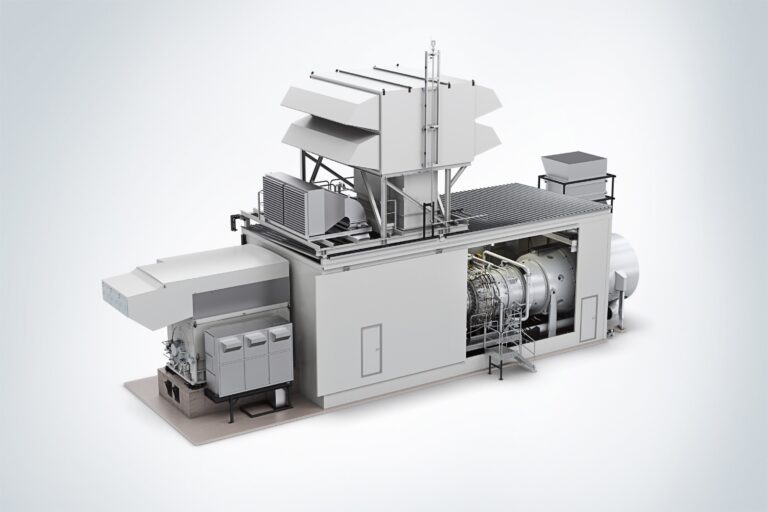

Gas turbine

At their core, gas turbines operate on the Brayton cycle. The process begins as ambient air is drawn into the unit and pressurized by a multi-stage compressor. This compressed air then enters a combustion chamber, where it is mixed with fuel and ignited, creating a high-temperature, high-pressure gas stream. This hot gas expands rapidly through a series of turbine blades, causing the turbine to rotate at high speed. A significant portion of this rotational energy is used to drive the compressor, while the remaining power drives the output shaft connected to a generator or other industrial machinery.

Key Applications of Gas Turbines

The versatility of gas turbines allows them to be deployed in several critical configurations, each tailored to specific energy and operational demands:

Simple Cycle Power Generation: In this setup, the gas turbine directly drives a generator to produce electricity. This configuration is valued for its rapid start-up capability, making it ideal for meeting peak electricity demand or for providing emergency power.

Combined Cycle Power Plants (CCPP): Representing the pinnacle of thermal efficiency, a combined cycle plant uses the hot exhaust gas from the turbine to generate steam in a Heat Recovery Steam Generator (HRSG). This steam then drives a separate steam turbine, producing additional electricity. This process significantly boosts overall plant efficiency, often exceeding 60%.

Mechanical Drive: Gas turbines are frequently used as a direct power source for large rotating equipment. They are essential in the oil and gas industry for driving compressors that move natural gas through pipelines and for powering large pumps in various industrial processes.

Combined Heat and Power (CHP) / Cogeneration: Similar to a combined cycle plant, a CHP system captures the turbine’s exhaust heat. However, instead of using all the steam to generate electricity, a portion is used directly for industrial process heating, district heating, or other thermal applications, maximizing the total energy utilization of the fuel.

We specialize in the design, selection, and supply of gas turbine packages across a wide power spectrum, ensuring the perfect match between technology and your specific requirements. Our portfolio is categorized based on power output and internal aerodynamic design, offering superior performance from micro-scale applications to large industrial power generation.

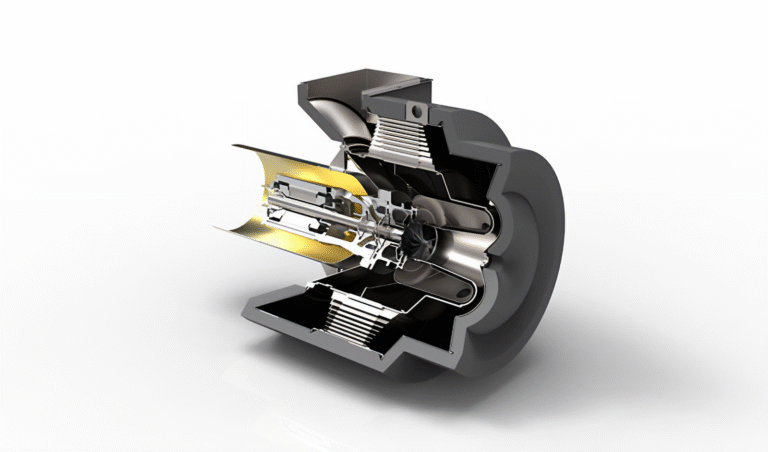

Micro Gas turbines 25 kW - 1 MW

These small-scale units are primarily designed for decentralized and localized energy needs. Their compact size, minimal maintenance requirements, and ultra-low emission profile make them ideal for distributed generation, combined heat and power (CHP) systems for commercial buildings, small industrial facilities, and backup power applications. They are especially valued for their flexibility and the ability to operate on a variety of fuels, including biogases.

Design Principle: Operates on the Brayton cycle, typically utilizing a single shaft design with a centrifugal compressor, radial turbine, and a recuperator (heat exchanger) for enhanced thermal efficiency.

Power Output: Standard electrical generation capacity ranges from 25 kW up to 1,000 kW (1 MW), scalable based on the application’s demand profile.

Operating Speed: Operates at very high rotational speeds (30,000 – 90,000 RPM), using a high-frequency power electronics system to convert power to grid frequency (50 or 60 Hz).

Thermal Efficiency (Electrical): High-efficiency units achieve 28% – 35% electrical efficiency. When configured for Combined Heat and Power (CHP), overall thermal utilization can exceed 80%.

Emissions Profile: Known for their ultra-low emissions due to advanced lean-premix combustion technology, typically meeting stringent environmental regulations (e.g., sub 9 ppm NOx levels).

Fuel Flexibility: Capable of operating on a wide variety of gaseous and liquid fuels, including Natural Gas, LPG, Diesel, and opportunity fuels like Landfill Gas and Biogas.

Installation: Designed as compact, modular, skid-mounted units with a small footprint, ideal for distributed generation and easy installation in commercial or small industrial settings.

Maintenance & Operation: Features air-bearing technology (eliminating oil lubrication systems in some models), resulting in minimal vibration, very low maintenance requirements, and long service intervals.

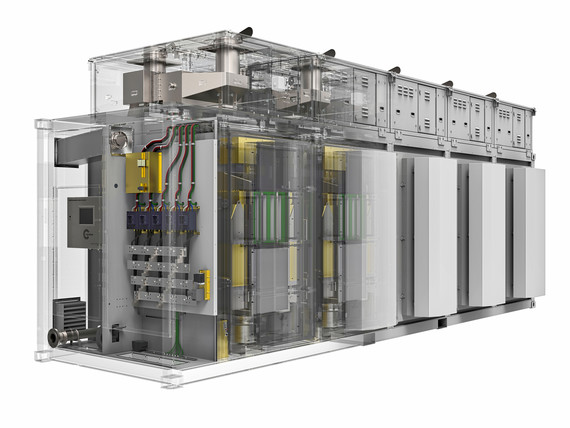

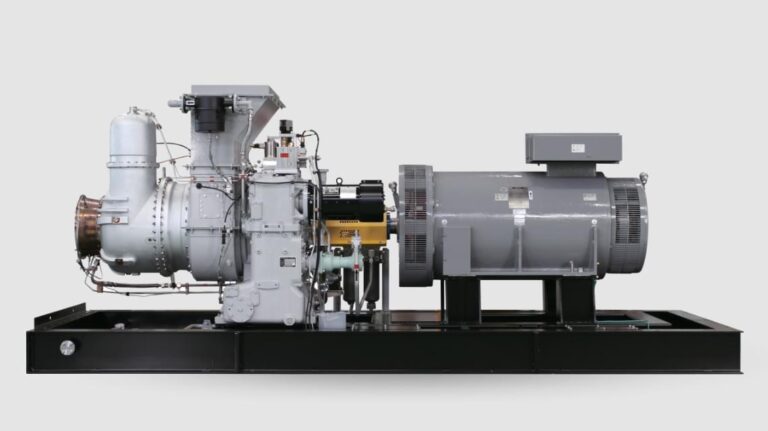

Industrial Gas turbines (1 - 10 MW) - Centrifugal Compressor/Axial or Radial Turbine Design

This category of robust industrial turbines is characterized by its internal design, which utilizes a centrifugal compressor coupled with an axial or radial turbine.

Design Principle: Characterized by its use of a rugged centrifugal compressor, often coupled with an axial or radial power turbine. This design prioritizes operational stability and robust handling of varying airflows.

Power Output: Electrical generation or mechanical drive output capacity typically ranges from 1 MW up to 10 MW, serving mid-sized industrial and oil & gas needs.

Operational Robustness: Centrifugal compression provides a wider operating envelope and is highly resilient to atmospheric dust and contaminants, minimizing performance degradation in harsh environments.

Thermal Efficiency: Electrical efficiency generally falls in the 25% – 32% range in simple cycle. When integrated into CHP (Cogeneration) systems, overall thermal utilization often exceeds 75%.

Installation: Supplied as robust, skid-mounted packages with protective enclosures, designed for permanent installation in remote or industrial facility locations.

Maintenance & Durability: Known for their simplified design relative to axial units, offering high availability, longer service intervals, and reduced complexity in major overhaul procedures.

Fuel Flexibility: Typically engineered for primary operation on Natural Gas, with robust capabilities for handling liquid fuels (e.g., diesel) for backup and dual-fuel operation.

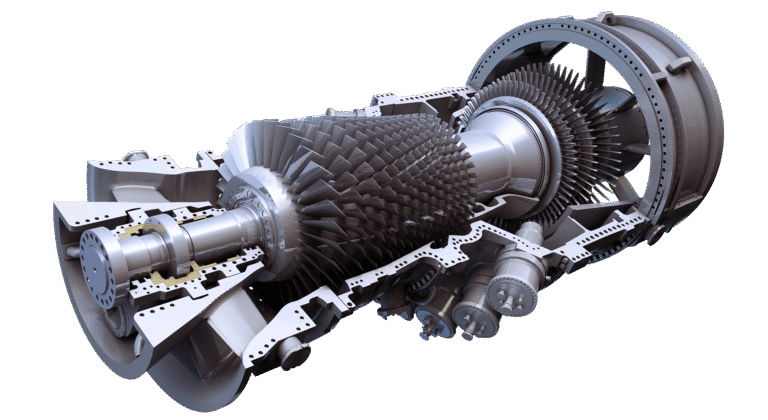

Industrial Gas turbines (1 - 10 MW) - Axial Compressor/Axial Turbine Design

These higher-performance industrial units incorporate an axial compressor paired with an axial turbine, representing a design optimized for efficiency and flow.

Design Principle: Characterized by multiple stages of an axial flow compressor and an axial flow power turbine. This configuration is optimized for handling very large airflow volumes at higher pressure ratios.

Power Output: Electrical generation or mechanical drive capacity typically ranges from 1 MW up to 10 MW, aimed at large-scale industrial or small utility power generation.

Thermal Efficiency (Electrical): High-efficiency focus leads to strong simple cycle electrical efficiencies, often in the 30% – 38% range. This efficiency is paramount when maximizing electrical output.

Combined Cycle Potential: Ideal for integration into small to mid-sized Combined Cycle Power Plants (CCPP), where the high exhaust temperature is used to significantly boost the overall plant efficiency (often exceeding 75% in CHP).

Primary Application Focus: Preferred for power generation and applications where maximizing energy efficiency, minimizing fuel consumption, and integrating with Heat Recovery Steam Generators (HRSGs) are critical.

Rotor Speed: Operates at high speeds, though often lower than micro-turbines, requiring a reduction gear or direct drive system for power generation equipment.

Installation: Supplied as pre-assembled, fully enclosed packages, requiring robust foundations typical of high-speed, high-power turbomachinery.

Operational Sensitivity: While highly efficient, axial compressors are generally more sensitive to fouling (kir birikimi) and foreign object damage (FOD) than centrifugal designs, requiring robust air filtration and maintenance protocols.

Our gas turbine solutions are engineered to provide a range of strategic benefits for modern industrial and utility applications:

Operational Flexibility

Gas turbines can be started, synchronized, and brought to full load in a matter of minutes, providing exceptional flexibility for peaking power, grid stabilization, and emergency backup services.

Fuel Versatility

Engineered to operate reliably on a wide spectrum of fuels, including natural gas, diesel, and increasingly, low-carbon alternatives like hydrogen blends and biofuels, offering adaptability to local fuel availability and environmental regulations.

High Reliability

With fewer moving parts than reciprocating engines of similar capacity, gas turbines are known for their high availability and long service intervals, ensuring consistent and predictable performance.

High Power Density

Their compact size relative to their substantial power output makes them an ideal choice for installations with space constraints, including offshore platforms and urban power plants.

Interested in discovering more?

Contact us today! We’re eager to assist you in finding the perfect solution, product, or service.

Fevol provides innovative industrial process solutions, driving sustainability and efficiency in the energy sector. We engineer and provide smart, reliable systems for a greener future.

Useful Links

Our Expertise

Contact Us

Barbaros Mahallesi, Begonya Sk. Nidakule Ataşehir Batı No:1 Ataşehir / Istanbul, Türkiye

info@fevoltech.com

Copyright 2025, Fevol. All Rights Reserved.