Heat exchangers

Heat exchangers are fundamental components in nearly every industrial process, responsible for the efficient transfer of thermal energy between two or more fluids without allowing them to mix. Whether your application demands the robust integrity of a Shell & Tube Heat Exchanger or the compact, high-efficiency performance of a Plate Heat Exchanger, selecting the right technology is critical to maximizing your system’s operational economy. Our specialized heat exchangers are engineered for precise temperature control, energy optimization, and reliable performance across the most demanding industrial environments.

Heat exchangers

At FEVOL, we understand that effective thermal management is the cornerstone of industrial efficiency. Our comprehensive heat exchanger portfolio offers meticulously engineered solutions, including the time-tested Shell & Tube Heat Exchanger for applications demanding maximum robustness, high pressures, and extreme temperatures. Complementing this, we offer high-performance Plate Heat Exchangers, designed for maximum thermal efficiency and a compact footprint, ideal for clean fluid applications and tight spaces.

We guide our clients through a precise selection process, ensuring the chosen unit—whether it relies on the durability of the shell and tube design or the superior heat transfer coefficient of the plate design—is perfectly matched to the fluid properties and thermal duty cycle of their specific process, delivering reliable performance and long-term energy savings.

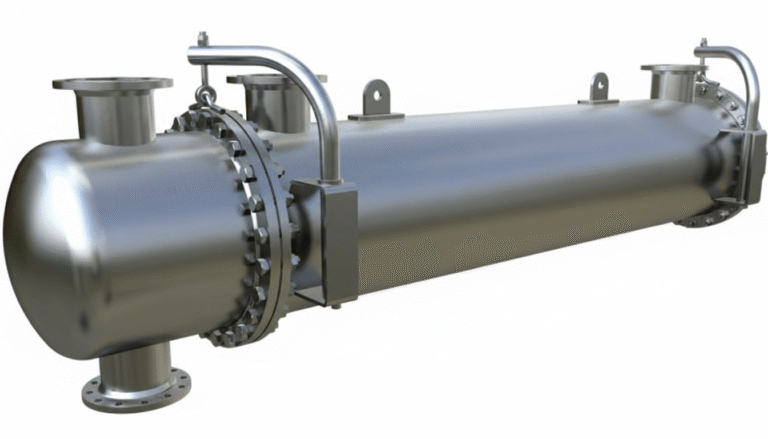

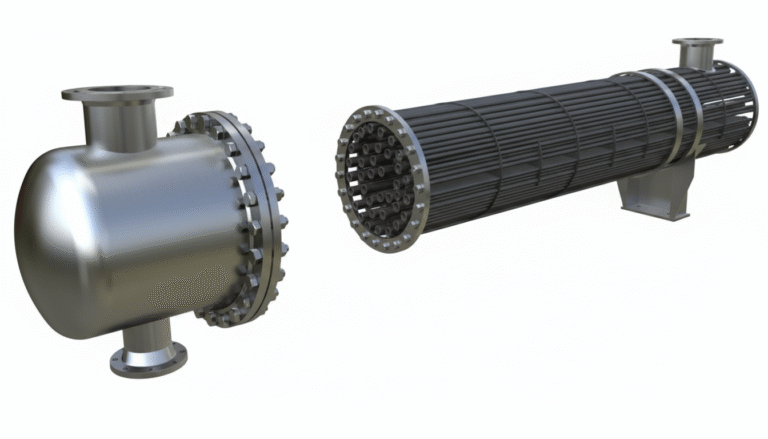

Shell & Tube Heat exchanger

The Shell & Tube Heat Exchanger represents the traditional and most versatile design in industrial applications.

Design: This unit consists of a bundle of tubes enclosed within a cylindrical shell. One fluid flows inside the tubes (tube side), while the second fluid flows outside the tubes, through the shell (shell side). Baffles direct the flow on the shell side to increase turbulence and enhance heat transfer.

Key Advantages:

Robustness: Excellent tolerance for high operating pressures and temperatures.

Durability: Suitable for harsh or dirty fluids, as tube cleaning access is relatively straightforward.

Flexibility: Highly customizable based on tube count, length, and layout for specific thermal duties.

Typical Applications: High-pressure steam condensers, oil and gas processing, chemical plants, and applications involving extreme temperature differentials.

Plate type Heat exchanger

The Plate Heat Exchanger (PHE) is a compact and highly efficient alternative, primarily used for fluid-to-fluid heat transfer.

Design: It uses a series of thin, embossed metal plates separated by gaskets. The plates are pressed together, creating channels through which the hot and cold fluids flow in a counter-current pattern. The corrugated surface induces high turbulence.

Key Advantages:

High Thermal Efficiency: The large surface area and turbulent flow result in a very close temperature approach and exceptional efficiency.

Compactness: Requires significantly less floor space than a Shell & Tube unit for the same thermal duty.

Serviceability: Easy to disassemble (break apart) for cleaning and inspection of all heat transfer surfaces.

Typical Applications: HVAC systems, dairy and food processing (where hygiene is critical), general utility duties, and low-viscosity fluid applications.

Key benefits of our Heat exchanger solutions (Shell & Tube and Plate Types)

Optimal Energy Recovery

Designed to maximize the heat transfer efficiency between two process streams, significantly minimizing external energy consumption and boosting the overall thermal effectiveness of your plant.

Precision Thermal Sizing

Solutions are precisely engineered and selected (choosing between the robustness of Shell & Tube or the efficiency of Plate) to guarantee the ideal thermal approach temperature and flow rate for the specific process duty.

Robustness for Demanding Environments (Shell & Tube)

Engineered to withstand extreme operating conditions, including very high system pressures, elevated temperatures, and the demands of handling dirty or highly viscous media.

Superior Efficiency in Compact Design (Plate Type)

Achieve exceptional heat transfer coefficients within a minimal physical footprint, making them highly effective for fluid-to-fluid duties, especially in space-constrained or high-hygiene applications.

Simplified Maintenance Access

Designs ensure ease of cleaning and serviceability—either via straightforward mechanical cleaning of the tubes (Shell & Tube) or through quick disassembly for access to the plates (Plate Type)—minimizing costly downtime.

Corrosion and Material Integrity

Constructed using high-grade materials (ranging from carbon steel to stainless steel and specialized alloys) tailored exactly to the process fluids, ensuring maximum asset longevity and preventing process contamination.

Interested in discovering more?

Contact us today! We’re eager to assist you in finding the perfect solution, product, or service.

Fevol provides innovative industrial process solutions, driving sustainability and efficiency in the energy sector. We engineer and provide smart, reliable systems for a greener future.

Useful Links

Our Expertise

Contact Us

Barbaros Mahallesi, Begonya Sk. Nidakule Ataşehir Batı No:1 Ataşehir / Istanbul, Türkiye

info@fevoltech.com

Copyright 2025, Fevol. All Rights Reserved.