Heat Recovery Steam Generators

In the pursuit of maximum industrial efficiency and sustainability, waste heat is the greatest untapped energy resource. Our Heat Recovery Steam Generators (HRSGs) are engineered to capture high-temperature exhaust and process heat, converting it into valuable steam for power generation or process heating. This crucial technology allows your facility to dramatically increase overall thermal efficiency, reduce reliance on auxiliary firing, and significantly lower environmental emissions, transforming energy loss into a reliable and sustainable power source.

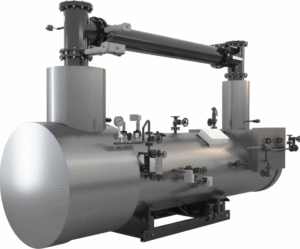

Heat Recovery Steam Generator (HRSG)

The Heat Recovery Steam Generator (HRSG) has always been a cornerstone of industrial efficiency, capturing high-grade waste heat—typically from gas turbines or industrial processes—and converting it into valuable steam power. However, in today’s highly competitive industrial environment, maximizing thermal efficiency and minimizing environmental impact are paramount to long-term financial sustainability. The modern HRSG stands as a strategic asset, converting energy that was previously lost as exhaust heat into a valuable, reliable steam supply. We recognize that true engineering excellence lies in transforming every joule of available energy into a productive output. Our commitment is to provide customized, high-reliability HRSG systems that allow your facility to achieve peak performance levels, secure a competitive edge, and dramatically reduce reliance on auxiliary fuel firing.

The Heat Recovery Steam Generator (HRSG) is an essential asset that transforms costly waste heat—typically from gas turbines, engine exhausts, or process streams—into valuable steam or hot water. While the core principle remains consistent, modern HRSGs incorporate continuous engineering advancements to achieve unparalleled levels of thermal capture, operational stability, and system durability. These innovations are centered on enhancing internal efficiency and protecting the long-term integrity of the unit.

Engineered Reliability by FEVOL

We recognize that an HRSG must be as reliable as the primary equipment it serves. We don’t just supply equipment; we engineer custom solutions. Our team designs the HRSG configuration—including optimal tube materials and advanced control systems—to precisely match your unique exhaust conditions and output requirements. We deliver a durable, low-maintenance system that transforms energy loss into a reliable, valuable, and sustainable power source for decades to come.

Design: Hot exhaust flue gases flow through tubes, which are submerged within a large vessel of water. This design is primarily used for recovery applications involving lower exhaust temperatures or smaller gas volumes.

Applications: Typically used for applications requiring low-to-medium steam capacity and pressure (e.g., smaller engine exhausts, light process applications, or commercial heating). They are well-suited when steam quality stability is the priority.

Advantages: Lower initial capital cost, robust construction, large water inventory provides a stable steam supply, and they are excellent at dampening the impact of sudden exhaust flow fluctuations.

Trade-offs: Limited to lower pressures and capacities due to the large pressure vessel thickness required. They offer slower response time during start-up compared to water-tube designs.

Design: Water flows through tubes while hot exhaust gases from the primary source (e.g., gas turbines) pass around them. The design allows for modular stacking of heat sections (economizer, evaporator, superheater).

Applications: Essential for operations demanding high steam capacities, high pressures, and superheated steam (common in utility-scale combined cycle power plants, large chemical complexes, and where gas turbine exhaust temperatures are very high).

Advantages: Rapid response to changes in gas turbine load, ability to achieve extremely high pressures (up to 180 bar or more), and a smaller relative footprint due to lower water inventory. Can handle very large exhaust gas flows.

Trade-offs: Higher initial capital cost, requires more complex and rigorous water treatment due to the high heat transfer rates in the tubes, making them susceptible to scaling and corrosion if water quality is not managed meticulously.

Heat Recovery Steam Generator (HRSG)

HRSGs are strategic assets that deliver immediate returns by integrating seamlessly into your existing operations:

Maximized Efficiency

By generating steam without burning additional fuel, an HRSG dramatically increases your plant’s overall thermal efficiency, leveraging the energy you've already paid for.

Reduced Operating Costs

Converting waste heat directly into process steam or power significantly cuts down on auxiliary fuel consumption, leading to immediate and sustainable savings.

Environmental Responsibility

Lower consumption of fossil fuels directly translates to a reduced carbon footprint, ensuring your operations meet modern sustainability and compliance goals.

Seamless Integration

Whether capturing heat from gas turbines, engines, or specialized process furnaces, our units are designed for straightforward integration, enhancing your system without major operational disruption.

Interested in discovering more?

Contact us today! We’re eager to assist you in finding the perfect solution, product, or service.

Fevol provides innovative industrial process solutions, driving sustainability and efficiency in the energy sector. We engineer and provide smart, reliable systems for a greener future.

Useful Links

Our Expertise

Contact Us

Barbaros Mahallesi, Begonya Sk. Nidakule Ataşehir Batı No:1 Ataşehir / Istanbul, Türkiye

info@fevoltech.com

Copyright 2025, Fevol. All Rights Reserved.