Mobile Containerized Boiler Rooms

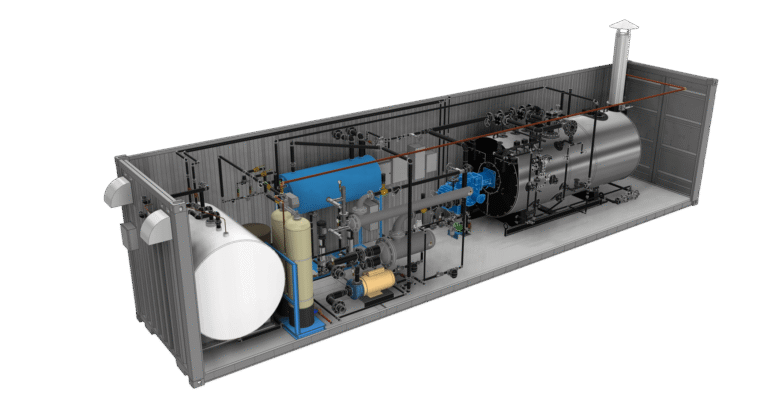

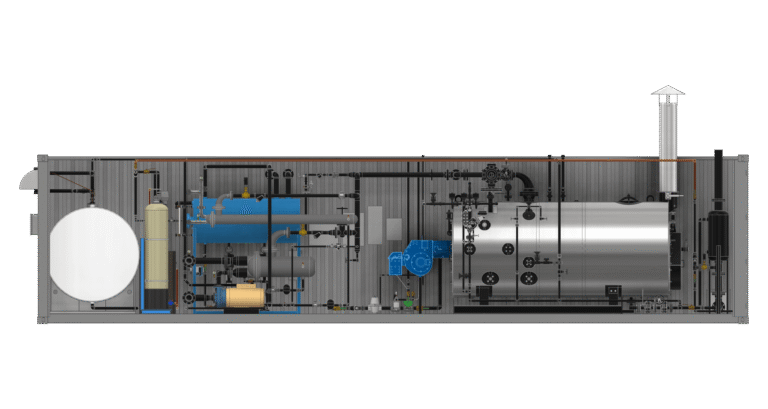

For industrial needs demanding rapid deployment, operational flexibility, or reliable emergency backup, our Mobile Containerized Boiler Rooms provide a complete, turnkey solution. These self-contained units integrate high-efficiency steam or hot water boilers, essential peripherals, and advanced controls into a single, pre-tested shipping container. This design minimizes on-site installation time and cost, ensuring immediate, reliable heating power exactly where and when your operation needs it.

Mobile containerized boiler rooms

Our Mobile Containerized Boiler Rooms offer a practical and efficient solution for reliable steam or hot water production where speed and operational flexibility are essential. These units arrive as complete, self-contained heating plants, integrating the main boiler, fuel system, feed water pumps, water treatment components, and all necessary control systems within a secure, standard shipping container. This “plug-and-play” approach significantly reduces the construction time and coordination required on your site, as the entire system is pre-piped, electrically commissioned, and factory-tested before delivery.

At FEVOL, we specialize in delivering these turnkey modular systems. We ensure that every containerized boiler room is engineered and manufactured to the highest standards of quality and safety, providing a robust, efficient, and readily deployable heating solution tailored precisely to meet your specific operational needs.

Mobile Containerized Steam Boiler

Boiler Design: Horizontal three-pass, wet-back fire-tube construction for high heat transfer rates and operational stability. (As optional, Coil type Fast Steam Generator or compact Water-Tube boiler design, optimized for reduced weight, rapid response times, and fast start-up/shutdown cycles.)

Steam Capacity: Standard output range typically available from 500 kg/h up to 15,000 kg/h, scalable based on container size.

Operating Pressure: Configurable for low-to-medium pressure applications, with standard design pressures up to 25 bar.

Container Specifications: Housed within a certified and modified ISO shipping container (typically 20ft or 40ft) for easy road, rail, and sea transport.

Turnkey Integration: Fully integrated package including the main boiler, burner, feedwater pumps, make-up water system, deaerator system and blowdown vessel.

Thermal Efficiency: High base efficiency guaranteed at 88% – 90% (on LHV), with options for integrated economizer units for further heat recovery.

Fuel Flexibility: Engineered to accommodate various fuel types, including natural gas, LPG, and light oil, often featuring quick-change burner systems.

Control System: Equipped with an advanced PLC-based control panel for fully automated operation, remote diagnostics, and comprehensive safety management.

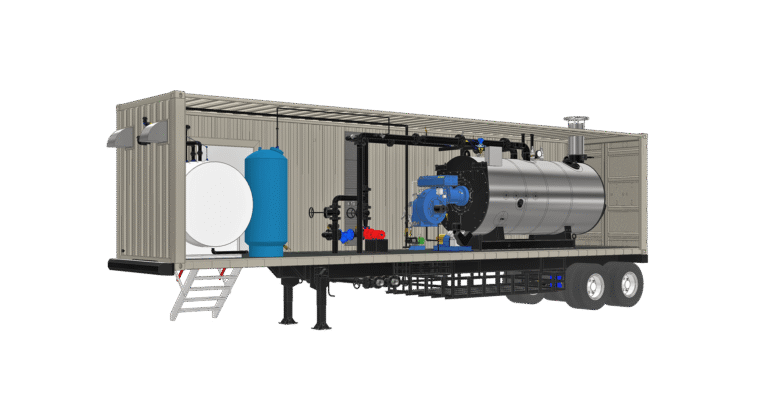

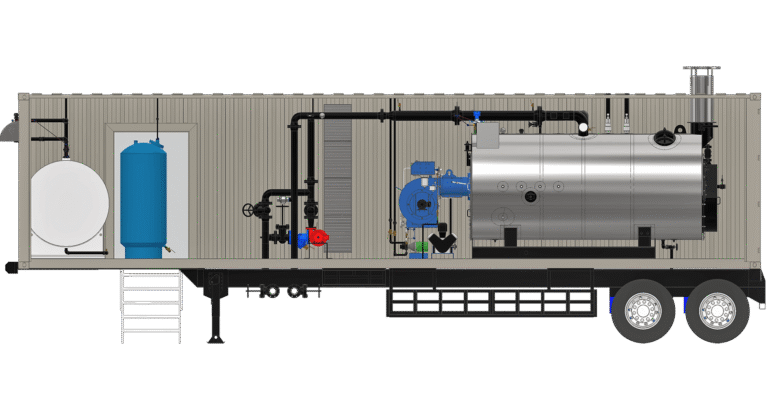

Mobile Trailer-mounted Containerized Steam Boiler

Boiler Design: Horizontal three-pass, wet-back fire-tube construction for high heat transfer rates and operational stability. (As optional, Coil type Fast Steam Generator or compact Water-Tube boiler design, optimized for reduced weight, rapid response times, and fast start-up/shutdown cycles.)

- Platform Design: Fully contained and mounted on a heavy-duty, certified road-legal trailer chassis, enabling rapid mobilization and relocation across sites.

Steam Capacity: Standard output range typically available from 500 kg/h up to 15,000 kg/h, scalable based on container size.

Operating Pressure: Configurable for low-to-medium pressure applications, with standard design pressures up to 25 bar.

Container Specifications: Housed within a certified and modified ISO shipping container (typically 20ft or 40ft) for easy road, rail, and sea transport.

Turnkey Integration: Fully integrated package including the main boiler, burner, feedwater pumps, make-up water system, deaerator system and blowdown vessel.

Thermal Efficiency: High base efficiency guaranteed at 88% – 90% (on LHV), with options for integrated economizer units for further heat recovery.

Fuel Flexibility: Engineered to accommodate various fuel types, including natural gas, LPG, and light oil, often featuring quick-change burner systems.

Control System: Equipped with an advanced PLC-based control panel for fully automated operation, remote diagnostics, and comprehensive safety management.

Whether it is a Fire-Tube Boiler, Water-Tube Boiler, or Fast Coil Steam Generator.

High Thermal Efficiency and Fuel Economy

All our products are equipped with advanced combustion technology and integrated economizers (optional/standard). This ensures maximum heat recovery while keeping fuel consumption to a minimum, significantly reducing long-term operating costs.

Low Emissions and Environmental Compliance

As part of our environmental commitment, all our steam systems feature Low NOx burners and precise combustion control as standard. This minimizes harmful emissions, ensures compliance with the strictest international standards, and contributes to sustainable operations.

Advanced Automation and Digital Control

As optional, steam system is equipped with modern PLC (Programmable Logic Controller)-based automation and user-friendly SCADA/HMI interfaces. This allows operators real-time data access, performance optimization, and guarantees safe, automatic operation.

Superior Safety and Reliability

All our designs adhere to the highest international safety standards (such as ASME and EN). Equipped with redundant safety systems, pressure relief valves, and automatic safety shutdown mechanisms, our products promise a long, trouble-free operating life.

Comprehensive Water Quality Management Integration

The lifespan and efficiency of steam systems are crucially dependent on water quality. Our products are designed for seamless integration with effective water treatment systems (deaerators, softeners). This prevents corrosion and scale buildup, thereby reducing maintenance needs and extending system life.

Flexible and Modular Design Approach

Acknowledging the variability of industrial requirements, our systems feature a modular structure that is adaptable across a wide capacity range and can accommodate future expansion. This allows us to provide tailor-made solutions suitable for diverse load profiles and facility layouts.

Interested in discovering more?

Contact us today! We’re eager to assist you in finding the perfect solution, product, or service.

Fevol provides innovative industrial process solutions, driving sustainability and efficiency in the energy sector. We engineer and provide smart, reliable systems for a greener future.

Useful Links

Our Expertise

Contact Us

Barbaros Mahallesi, Begonya Sk. Nidakule Ataşehir Batı No:1 Ataşehir / Istanbul, Türkiye

info@fevoltech.com

Copyright 2025, Fevol. All Rights Reserved.