Steam boilers & Steam generators

Our product and component sales are about more than just delivering parts. The foundation of every successful industrial operation is a combination of reliable systems and high-quality components. At FEVOL, we understand that whether your project requires a full-scale plant or a single, critical part, the right choice is essential for long-term performance and efficiency. We provide a wide range of products, from expertly engineered, complete systems to the individual components that keep them running.

Steam solutions

Steam generation is the indispensable core of modern industry, providing the thermal energy necessary for processes ranging from power generation and chemical synthesis to sterilization and heating. The steam boiler or generator is not merely a piece of equipment; it is a critical, long-term asset whose performance directly dictates a plant’s efficiency, operating costs, and environmental compliance. Selecting the right steam system requires a deep understanding of fluid dynamics, combustion science, metallurgy, and operational strategy.

Industrial steam boilers are primarily categorized by the relationship between the hot combustion gases and the water being heated. The choice between them is determined by capacity, pressure requirements, and load responsiveness.

Our comprehensive portfolio is engineered to deliver robust, high-performance steam solutions, ensuring we perfectly match your facility’s unique operational demands. We offer meticulously designed Fire-Tube Steam Boilers for stable, reliable low-to-medium pressure steam, alongside powerful Water-Tube Steam Boilers built for dynamic, high-capacity, and high-pressure industrial environments. Furthermore, we provide Fast Coil Steam Generators to meet critical demands for rapid start-up and quick response in batch processes. This specialized range allows us to tailor the ideal system for your specific industrial needs, from stable continuous operation to agile, high-pressure demands.

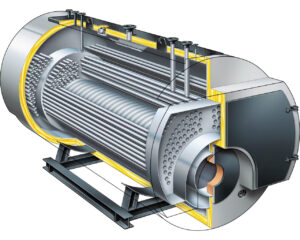

Fire tube steam boilers

Design: Hot flue gases flow through tubes, which are submerged within a large vessel of water. (learn more)

Applications: Typically used for applications requiring low-to-medium steam capacity and pressure (often up to 30 tonnes/hour and 25 bar). They are common in commercial heating, small processing plants, and laundries.

Advantages: Lower initial capital cost, robust construction, large water inventory provides a stable steam supply, and excellent dampening against sudden load fluctuations.

Trade-offs: Slower response time during ramp-up, and limited to lower pressures and capacities due to the large pressure vessel thickness required.

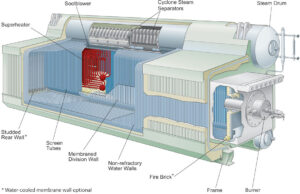

Water tube steam boilers

Design: Water flows through tubes that are exposed to hot combustion gases in the furnace.

Applications: Essential for operations demanding high steam capacities, high pressures, and superheated steam (common in utility power plants, large-scale chemical complexes, and refineries).

Advantages: Rapid response to sudden load changes, ability to achieve extremely high pressures (up to 180 bar or more), and smaller relative footprint due to lower water inventory.

Trade-offs: Higher initial capital cost, requires more complex and rigorous water treatment due to the high heat transfer rates in the tubes.

Fast steam generators with coil

Design: Water is forcibly pumped through a long, helical tube (the serpentine coil) surrounded by hot combustion gases. This design principle relies on forced circulation and contains a significantly smaller volume of water than conventional boilers.

Applications: Ideal for industrial applications requiring rapid steam availability and frequent cycling, such as batch processing, standby power generation, and facilities with severe space constraints. Typically used for medium-to-high pressure steam needs.

Advantages: Ultra-fast start-up (often 5–10 minutes to full pressure), inherent safety due to low stored energy (low explosion risk), and a remarkably smaller physical footprint compared to fire-tube units of similar capacity.

Trade-offs: Highly susceptible to poor water quality (requires meticulous water treatment to prevent scale buildup in the narrow coils), and servicing or coil replacement procedures can be more complex than standard boiler maintenance.

Whether it is a Fire-Tube Boiler, Water-Tube Boiler, or Fast Coil Steam Generator.

High Thermal Efficiency and Fuel Economy

All our products are equipped with advanced combustion technology and integrated economizers (optional/standard). This ensures maximum heat recovery while keeping fuel consumption to a minimum, significantly reducing long-term operating costs.

Low Emissions and Environmental Compliance

As part of our environmental commitment, all our steam systems feature Low NOx burners and precise combustion control as standard. This minimizes harmful emissions, ensures compliance with the strictest international standards, and contributes to sustainable operations.

Advanced Automation and Digital Control

As optional, steam system is equipped with modern PLC (Programmable Logic Controller)-based automation and user-friendly SCADA/HMI interfaces. This allows operators real-time data access, performance optimization, and guarantees safe, automatic operation.

Superior Safety and Reliability

All our designs adhere to the highest international safety standards (such as ASME and EN). Equipped with redundant safety systems, pressure relief valves, and automatic safety shutdown mechanisms, our products promise a long, trouble-free operating life.

Comprehensive Water Quality Management Integration

The lifespan and efficiency of steam systems are crucially dependent on water quality. Our products are designed for seamless integration with effective water treatment systems (deaerators, softeners). This prevents corrosion and scale buildup, thereby reducing maintenance needs and extending system life.

Flexible and Modular Design Approach

Acknowledging the variability of industrial requirements, our systems feature a modular structure that is adaptable across a wide capacity range and can accommodate future expansion. This allows us to provide tailor-made solutions suitable for diverse load profiles and facility layouts.

Interested in discovering more?

Contact us today! We’re eager to assist you in finding the perfect solution, product, or service.

Fevol provides innovative industrial process solutions, driving sustainability and efficiency in the energy sector. We engineer and provide smart, reliable systems for a greener future.

Useful Links

Our Expertise

Contact Us

Barbaros Mahallesi, Begonya Sk. Nidakule Ataşehir Batı No:1 Ataşehir / Istanbul, Türkiye

info@fevoltech.com

Copyright 2025, Fevol. All Rights Reserved.