Thermal oil heater

For industrial processes requiring stable, high-temperature heat transfer without the operational complexities of high-pressure steam, Thermal Oil Heaters offer the ideal solution. Our thermal fluid systems deliver precise and reliable process heat up to 400 C degree at near-atmospheric pressure. This technology ensures optimal efficiency, superior safety, and consistent thermal control for your most demanding applications.

Thermal oil heater

Modern thermal fluid technology is rapidly evolving, shifting focus toward operational precision and sustainability. Recent developments center on optimized serpentine coil design for improved heat flux and reduced degradation of the thermal fluid over time. Crucially, systems now feature advanced digital controls utilizing predictive algorithms for ultra-stable temperature output and sophisticated burner management, leading to maximum fuel efficiency and minimal emissions. Furthermore, the integration of flue gas heat recovery (economizers) into the design is becoming standard, significantly boosting the overall thermal efficiency of the entire system.

At FEVOL, our commitment is to ensure these engineering advancements translate into tangible, long-term operational benefits for your facility. We integrate the latest technologies into every thermal oil heater we supply, from precision coil manufacturing to sophisticated digital control systems. Our approach is holistic: we don’t just provide equipment; we offer end-to-end service, covering the initial system design, professional installation, and expert commissioning. This meticulous oversight guarantees that your new thermal oil heater delivers maximized efficiency, superior digital control, and reliable, safe high-temperature heat transfer throughout its entire operational lifecycle.

Features of Thermal oil heater

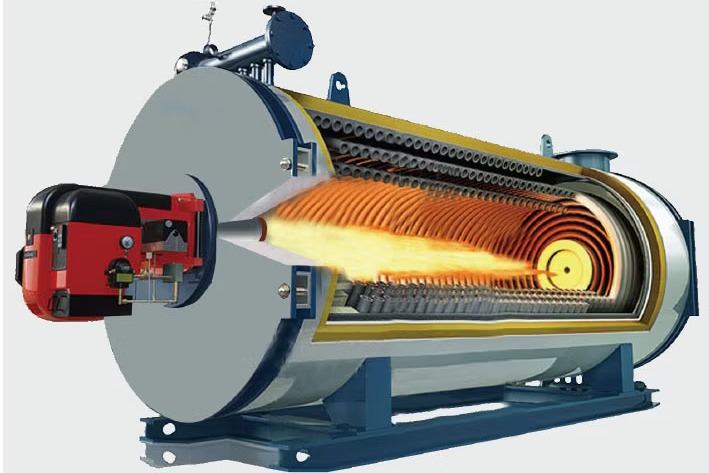

Design: Thermal oil (synthetic or mineral-based fluid) is heated via forced circulation within a coil or tube arrangement exposed to combustion gases generated by a burner. The system operates in a completely closed loop and at near-atmospheric pressure to achieve high temperatures.

Applications: Indispensable for processes requiring high-temperature (typically 300 C – 400 C but low-pressure heat transfer. Widely used in the chemical, textile (stenter machines), food processing, asphalt production, wood (MDF/plywood presses), and petroleum industries.

Advantages: Achieves high temperatures without the substantial investment costs and heavy safety regulations required by high-pressure steam boilers. Corrosion and scaling risks within the system are minimal. Process temperature control is highly precise and stable.

Trade-offs: Thermal fluid cost is high, and oxygen/moisture control within the system must be meticulous to prevent fluid degradation (cracking). Fluid replacement/maintenance costs are also a factor.

Thermal Efficiency

The efficiency of thermal oil heaters varies depending on whether an additional heat recovery unit is employed:

Without Recuperator (Standard Operation): Typical Thermal Efficiency: 85-88% range.

With Recuperator (Economizer): Thermal efficiency increases to the 88-92% range, as some of the flue gas heat is used to preheat the fluid or combustion air.

The core heating unit where the thermal fluid is heated to the required process temperature.

Drives the heated thermal fluid from the heater to all heat consumers in the system.

Generates the combustion heat necessary to fire the thermal fluid heater in the combustion chamber.

Recovers residual heat from the flue gases before they exit the chimney, significantly boosting system efficiency.

Stores additional fluid for system makeup and holds the fluid during emergency cool-down.

Removes dissolved air and moisture (gases) from the fluid to prevent corrosion and oxidation.

Absorbs the volume increase of the fluid as temperature rises, maintaining the system's near-atmospheric pressure.

Benefits of Thermal oil heater

High-Temperature Precision

Achieve process temperatures up to 400 ∘C while operating at near-atmospheric pressure, offering precise heat required for demanding industrial applications without regulatory overhead.

Enhanced Safety and Simplicity

Eliminate the explosion risks, high construction costs, and complex regulatory burdens associated with high-pressure steam systems, simplifying boiler house operation and staffing requirements.

Stable and Consistent Control

Utilize the unique thermal properties of the fluid to deliver exceptionally stable and consistent temperature control, which is critical for ensuring product quality and process reliability in sensitive applications.

Maximum Asset Integrity

Since the system operates without water or steam, it completely eliminates the risks of internal corrosion, scaling, and freezing, significantly reducing long-term maintenance needs and extending the system’s lifespan.

Interested in discovering more?

Contact us today! We’re eager to assist you in finding the perfect solution, product, or service.

Fevol provides innovative industrial process solutions, driving sustainability and efficiency in the energy sector. We engineer and provide smart, reliable systems for a greener future.

Useful Links

Our Expertise

Contact Us

Barbaros Mahallesi, Begonya Sk. Nidakule Ataşehir Batı No:1 Ataşehir / Istanbul, Türkiye

info@fevoltech.com

Copyright 2025, Fevol. All Rights Reserved.